- Early detection of potential issues:

- Tolerance simulations allow for the virtual testing of the tolerance of products and production processes before they go into production. This allows for potential problems to be identified and addressed early on.

- Increase in product quality:

- Tolerance simulations contribute to increasing the quality of products by ensuring that all product parts are within the specified tolerances.

- Cost savings:

- Tolerance simulations can also contribute to reducing costs for rework and recalls by ensuring that products are within the specified tolerances from the beginning.

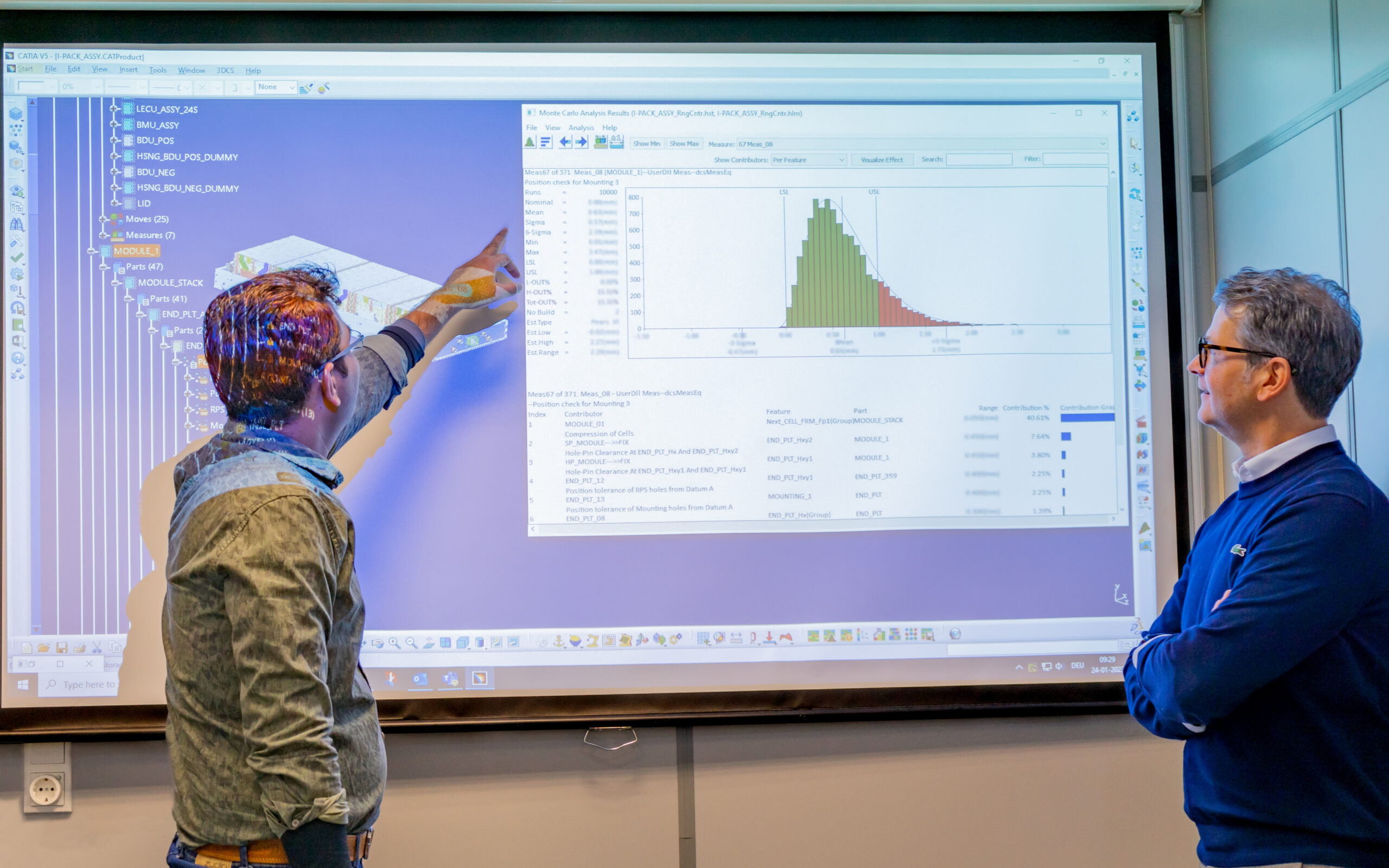

The picture shows a discussion of a battery pack that we simulate with the 3DCS system.